Get a better deal and start saving money today

Plant Design, Fabrication, Installation & Commissioning

Helium Synergies is equipped with experts in Mineral Processing Plant Design, Fabrication, Installation & Commissioning. Our general procedure for plant design includes ore testing, process definition, production of basic flowsheet, production of piping and instrument drawings, production of general arrangement drawings and conceptual models, equipment selection and specification, costing and preparation of definitive budget, production of final flowsheet, construction and commissioning.

Commissioning is a vital step near the end of a plant’s construction.

Its purpose is to hand over a safe, efficient and operation-ready facility to the owner. It is the planned coordination and execution of the final stages of construction and the beginning of production.

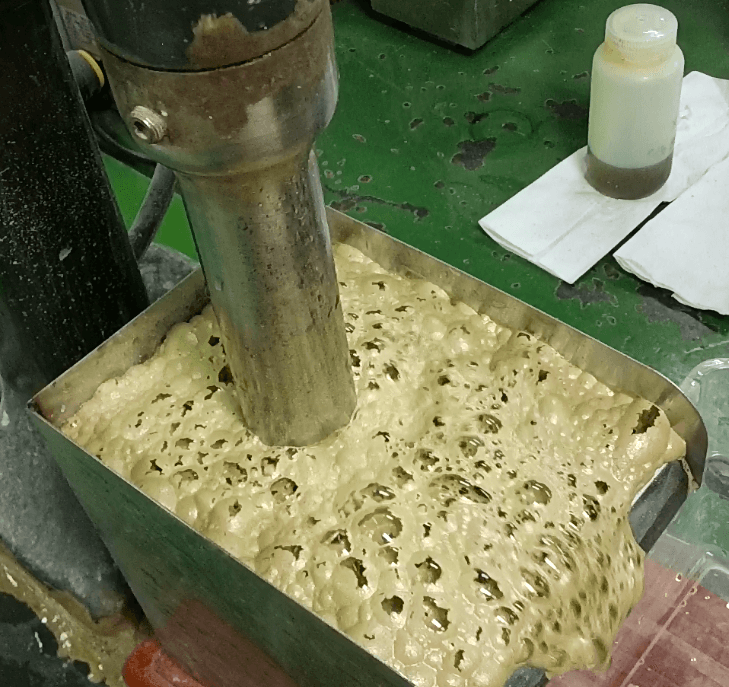

On & Off-site Metallurgical Testworks

Helium Synergies possess extensive Metallurgical testwork knowledge. During a met test-work, it is vital to determine mineralogy and process flowsheets so that extraction and processing can be achieved economically at commercial scale when identifying new deposits and planning for plant construction. It is used to evaluate how the resource material will respond to standard metallurgical processes such as flotation, gravity concentration, and leaching.

Read More

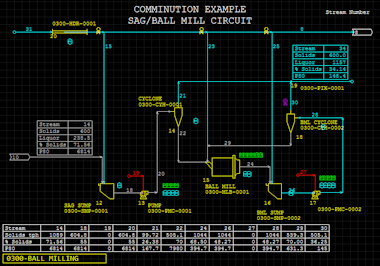

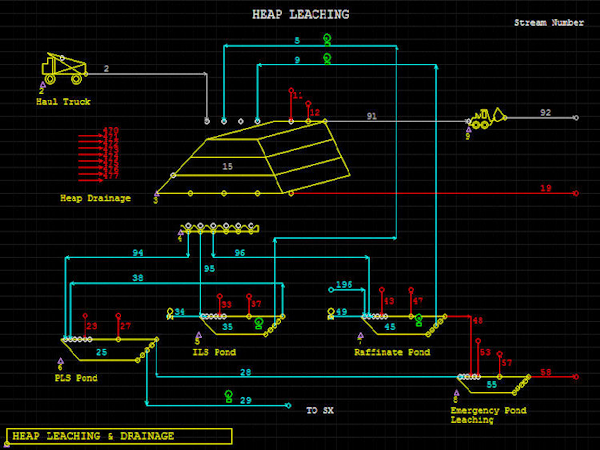

Flowsheet Development & Design

As a consultancy firm we have vast experience in flowsheet development and design. This is a crucial part of mining projects. It involves developing a plan for the processing of ore from crusher to concentrator. There are many factors that need to be considered when developing a flowsheet, including the type of rock being crushed, the desired product, energy and water requirements, production requirements, and the site’s climatic conditions.

Read More

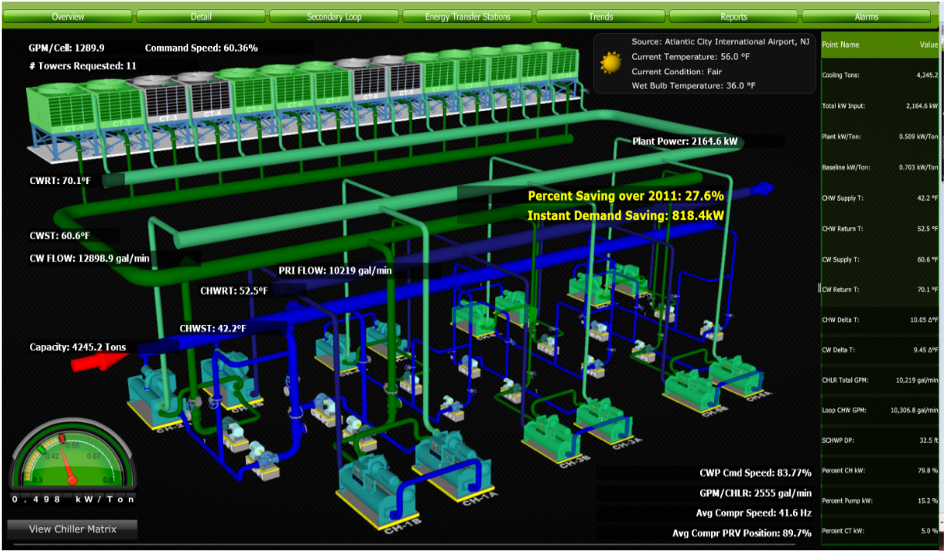

Plant Optimization & Troubleshooting

Helium Synergies is capable of conducting Plant Optimization and Troubleshooting in mineral processing plants. This is a process of improving productivity, reducing downtime, protecting the workforce and environment, and making the most cost-effective use of resources. It involves the use of technology to increase efficiency and reduce waste. As a mine progresses through its life cycle and as plant feed changes, the plant operation process should be continually reviewed and adjusted to maintain optimum performance.

Troubleshooting refers to the process of identifying, preventing and resolving issues that may arise during the operation of a mining plant. This can involve visual inspections, data analytics, remote expert support and other methods to ensure that equipment is installed as designed, controls and safety systems are fully functional, system punch list items are completed, and functional tests confirm conformance with design expectations for the equipment.

Analytical Testing(XRF & Wet Chemistry)

Helium Synergies also undertake Analytical testing. This refers to the use of various techniques to determine the elemental composition of materials. XRF (X-ray fluorescence spectroscopy) is one such technique. It is a non-destructive analytical technique that works by measuring the fluorescent (or secondary) X-rays emitted from a sample when excited by a primary X-ray source. Wet chemistry, on the other hand, refers to the use of traditional laboratory techniques such as titration and gravimetric analysis to determine the chemical properties of a substance.

Read More

Testwork Design & Supervision

It is in our DNA to design a Testwork & Supervise it. The process follows designing, managing, and evaluating all stages of a testwork program for a mining operation. This includes laboratory and pilot plant operation. The goal is to improve metal recovery and performance consistency through customized metallurgical flowsheet development.

The process involves selecting representative ore samples for the testwork program, evaluating the expected variability in process performance, and developing a scientific understanding of potential risks1. The expertise required includes crushing and grinding, materials handling, mineral processing, and hydrometallurgy

Modelling and Simulation (METSIM)

METSIM is a powerful program capable of modeling and simulating every known metallurgical and inorganic chemical process. In the context of mining, it is used by companies throughout the world to design, simulate and control operations from mine to tailings and everything in between.

Read MoreGet a Quote! Contact us